Decorative Metal Coatings Services

Chrome Plating

Elevate the allure of your metal surfaces with our flawless chrome plating service. Achieve a brilliant mirror-like finish that not only enhances aesthetics but also offers outstanding durability and resistance to corrosion.Chrome Plating Info...

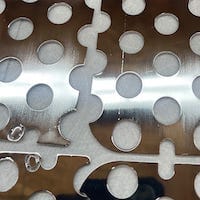

Electroless Nickel

With our cutting-edge electroless nickel plating, experience uniform coating that guarantees impeccable precision and increased wear resistance. This advanced process ensures a smooth, non-porous surface with exceptional adhesion properties.Electroless Nickel Info...

Copper Plating

Embrace the timeless elegance of copper with our expert copper plating service. Create an inviting and warm ambiance with the lustrous appearance of copper while also safeguarding your metal against deterioration.Copper Plating Info...

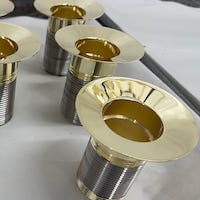

Brass Plating

Add a touch of sophistication to your metal items through our luxurious brass plating. The golden tones of brass exude opulence and charm, making your pieces stand out as exquisite works of art.Brass Plating Info...

Nickel Plating

Our nickel plating service is designed to provide a versatile and durable coating option. Enhance the functionality and appearance of your metal components, ensuring they withstand the test of time.Nickel Plating Info...

Special Finishes

We offer a range of distinctive and bespoke finishes to cater to your unique taste and style. From antiqued looks to custom patterns, our special finishes will add an exclusive touch to your metal pieces.Special Finishes Info...

Metal Polishing

Uncover the hidden brilliance of your metal surfaces with our meticulous metal polishing service. Our skilled craftsmen will revitalize your pieces, revealing their true luster and shine.Metal Polishing Info...

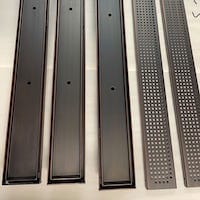

Powder Coating

Protect your metal items with our state-of-the-art powder coating service. This eco-friendly and robust coating solution not only adds a splash of color but also ensures outstanding resilience against environmental factors.Powder Coating Info...

Classic Car Restoration

Trust our expertise to restore your classic car to its former glory. Our passion for vintage vehicles combined with meticulous attention to detail will breathe new life into your cherished automobile.Classic Car Restoration Info...

Motorcycle Restoration

From retro classics to modern bikes, our motorcycle restoration service will transform your two-wheeled beauty into a head-turning masterpiece, capturing the thrill and nostalgia of the open road.Motorcycle Restoration Info...

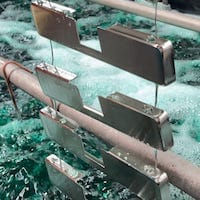

Boat and Yacht Restoration

Preserve the elegance of your maritime treasure with our top-notch boat and yacht restoration service. Revive its beauty and structural integrity, making it the centerpiece of any waterway.Boat and Yacht Restoration Info...

Home Decor Restoration

Give your home decor pieces a second chance at captivating charm through our restoration service. From cherished heirlooms to decorative centerpieces, we'll bring back the allure of your interiors.Home Decor Restoration Info...

Special Finishes

- Polished Chrome

- Polished Nickel

- Polished Brass

- Polished Copper

- Polished Bronze

- Satin Chrome

- Satin Nickel

- Satin Brass

- Satin Copper

- Satin Bronze

- Silver P/C

- Oil Rubbed Bronze

- Venetian Bronze

- Antique Peter

- Antique Brass

- Antique Copper

- Tumble Brass

- Tumble Nickel

- Tumble Copper

- Champagne Bronze

- German Bronze

- Gun Metal

- Polished Gold 24k

- Satin Gold 24k

- Black Nickel

- Electroless Nickel

- Matte Black P/C

- Semi Gloss Black

- High Gloss Black

- Candy Blue

- Candy Red

- Blue / Orange / Pink / Green

We can always do Matching samples or custom finishes.

About us

At Decorative Metal Coatings, we are a team of experts committed to providing exceptional metal finishing services. Our focus is on quality control, customer service, and delivering an outstanding experience for every client.

We use state-of-the-art technology and top-grade materials to ensure precise and long-lasting finishes on every project. Our quality control process is rigorous, ensuring that every piece that leaves our facility meets our high standards. Decorative Metal Coatings, believe in building strong relationships with our clients. That’s why we make it a priority to provide excellent customer service at every step of the way.

From the initial consultation to the final delivery, we strive to exceed your expectations. With decades of experience in the industry, our team of skilled craftsmen has the expertise to handle any project, no matter how complex. Whether you need a unique custom finish or a high-volume production run, we have the knowledge and experience to deliver outstanding results. Decorative Metal Coatings, takes pride in our work and are dedicated to providing the best possible service to our clients. Contact us today to learn more about our services and how we can help you achieve your metal finishing goals.

Decorative Metal Coatings offering a wide range of metal finishing services for various industries. Our services include: Antique Finishes, Black Nickel Plating, Brushed Only, Chemical Stripping Rust, Chrome Plating, Clear Powder Coating, Copper Plating, Electroless Nickel Plating, Electroplating, Gold Plating 24K, Nickel Plating, Patinas, Plating Services, Polishing, Powder Coating, Refurbish, Sand Blasting, Silver Plating, Tumble Finishes, Welding, Classic Car Restoration, Boat Restoration, and Motorcycle Restoration and more.

Our advanced techniques and use of high-quality materials ensure long-lasting and durable finishes. Whether you need plating for functional or cosmetic purposes, we have a solution for you. Our team of experts is committed to providing exceptional customer service and ensuring customer satisfaction. Contact us for all your plating needs.